Carbon steel or stainless steel welded parts

ACMH supplies welded parts or sub-assemblies for the industry. The manufacturing is done «Build to print». ACMH conducts an analysis of the performance requirements and selects the optimal manufacturing methods and potential subcontractors.

All activities meet ISO 9001 quality requirements. A formal Manufacturing Readiness Review (MRR) can be proposed. ACMH's welding processes are ISO 3834-2 certified, and the welders are qualified.

Welded aluminium parts

ACMH supplies simple parts or welded aluminium sub-assemblies for the industry. The manufacturing is done «Build to print».

ACMH analyzes the performance requirements and selects the optimal manufacturing methods. All activities meet ISO 9001 quality requirements.

A formal Manufacturing Readiness Review (MRR) can be offered to the client. ACMH's welding processes are ISO 3834-2 certified, and the welders are qualified.

Offshore wind turbine parts

Parts and sub-assemblies of offshore wind turbines operate in a harsh environment: high humidity, high salinity, vibrations, and infrequent maintenance due to challenging access conditions.

Requirements for materials, dimensional accuracy, welding, and corrosion protection are accordingly stringent. ACMH has welding certification according to ISO 3834-2.

Welds are inspected using dye penetrant or radiography. ACMH uses a LASER TRACKER for dimensional and angular verification. ACMH applies specific FROSIO requirements for anti-corrosion coating work.

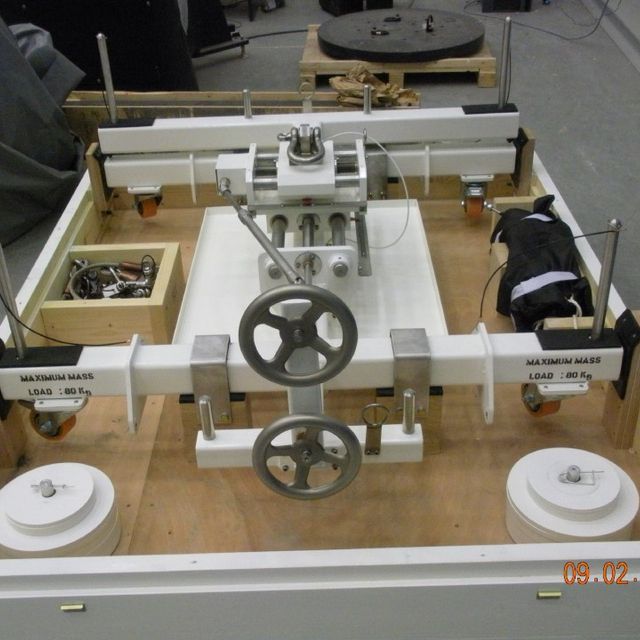

Large structures and tooling

ACMH designs and manufactures large-scale welded structures (e.g., 12 m x 6 m x 10 m, total weight 26 tonnes). The sizing is done by our engineering department following current standards or in compliance with customer requirements stated in their technical specifications.

ACMH also manufactures 'Build to print' according to customer plans. We recommend and conduct various tests (e.g., functional, lifting, or drop tests). Corrosion protection through painting coatings is preceded by surface preparation in our sandblasting/shot blasting booths.

20-foot containers - Industrial facilities

ACMH converts 20 and 40-foot maritime containers to create various industrial facilities. ACMH thermally insulates them and/or fireproofs them.

The containers are modified to accommodate an air ventilation system, air conditioning/heating, electrical supply, water/compressed air, alarms, and other functions.

Inside, ACMH creates suitable interfaces for equipment attachment: electrical transformers, pumps, storage racks, and spare parts warehouses. Structural verification is performed, and the maritime transport CSC certification can be retained.